kantver - Fotolia

How do I size a UPS unit?

Your data center UPS sizing needs are dependent on a variety of factors. Develop configurations and determine the estimated UPS capacity that will meet your current and future needs.

So you need an uninterruptible power supply unit, but you're having trouble sizing it. How do you figure it out?

Some uninterruptible power supply (UPS) systems are rated in kilowatts (kW) and others in kilo-volt-amperes (kVA). KW and kVA simply mean 1,000 watts (W) or 1,000 volt-amperes.

The basic rule of physics that watts = volts x amps is based on direct current circuits. Alternating current (AC) supplies buildings and equipment with energy. AC is more efficient for power companies to deliver, but when it hits the equipment's transformers, it exhibits a characteristic known as reactance.

Reactance reduces the useable power (watts) that is available from the apparent power (volt-amperes). The ratio of these two numbers is called the power factor (PF). Therefore, the actual power formula for AC circuits is watts = volts x amps x power factor. Unfortunately, the PF is rarely stated for most equipment, but it is always a number of 1.0 or less, and about the only thing with a 1.0 PF is a lightbulb.

For years, large UPS systems were designed based on a PF of 0.8, which meant that a 100 kVA UPS would only support 80 kW of real power load.

The majority of large, commercial UPS systems are now designed with a PF of 0.9. This recognizes that most of today's computing technology presents a PF of between 0.95 and 0.98 to the UPS. Some UPS systems are even designed with PFs of 1.0, which means the kVA and kW ratings are identical (100 kVA = 100 kW). However, since the IT load never presents a 1.0 PF, the actual load limit is the kVA rating for these UPS systems.

Regardless of how the ratings are stated, a 100 kVA UPS will never support an actual 100 kW load in the real world of the data center. The only way to really know how near you are to capacity is to read the UPS display. The Percent Load will tell you how close you are to the maximum in either kW or kVA, but be aware that this percentage will be displayed for the most heavily loaded phase, not for the total UPS capacity.

Large UPS systems are three-phase. In the U.S., you get 120 volts between any one of the phases and the neutral conductor, and you get 208 volts -- not 220 or 240 -- between any two phase conductors. In Europe, you get 230 or 240 volts between any phase and neutral. Connections aren't made between phases. Unless the loads on all three phases are close to equal, you won't be as close to maximum total capacity as the display says you are. You need to further check the loads on all three phases to determine that.

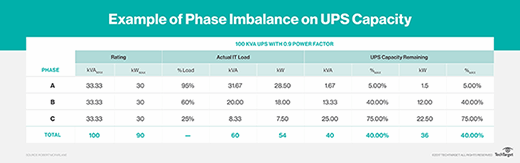

Take, for example, a 100 kVA UPS with a 0.9 PF, or 90 kW capacity. If Phase A is loaded to 95%, Phase B to 60% and Phase C to only 25%, the UPS will still have 40 kVA, or 36 kW, unused. That's 40% of its capacity remaining, despite the 95% reading.

Neither the kW nor the kVA capacity of the UPS can be exceeded, but because of the higher PF numbers, it is usually the kW rating that governs today. There are, however, some UPS systems on the market that are PF-corrected so that the kW and kVA ratings are the same.

Nameplate data on UPS systems

The biggest problem when figuring UPS unit sizing is determining their actual load. Many data hardware manufacturers still provide inadequate or misleading power data on their equipment. Bigger manufacturers are usually linked to or have a configurator on their websites. These tend to give quite accurate information if used correctly. But no tool can give you accurate total load estimation; it's up to you to develop realistic numbers.

Beware of using the nameplate. This is a legality rating and will usually give a much higher volt-ampere rating than the unit will ever draw. For example, consider a unit with a nameplate that reads 90 to 240 volts at 4 to 8 amps with a 500 W power supply. In the nameplate reading, the numbers are backward. The larger amperage goes with the lower voltage. If you assume a nominal 120 volts at 8 amps, you get 960 VA. A PF of 0.95 would yield 912 W. No power supply is that inefficient, and a power supply almost never runs at full power. Therefore, it is highly unlikely that this device will ever draw more than 500 W of power, but if you want to be really conservative, multiply by 1.1 and figure 550 W of input power.

Don't get trapped by dual-corded equipment. The power supplies share the load and either one is supposed to be able to carry the full load. Therefore, a unit with two 500 W supplies should still be figured as if it had only one.

UPS sizing capacity ratings

Once you have a realistic load estimate, plan to run a UPS around 80% of actual rated capacity. That provides headroom for peak operating conditions, gives you capacity to install a duplicate system before you decommission an old one or lets you absorb a little growth before you outgrow the unit. For a planned load of 80 kW, a 1.0 PF UPS rated at 100 kVA/100 kW should be sufficient if you keep your loads phase-balanced within about 5%. A UPS with a 0.9 PF will need a higher kVA rating; 125 kVA would give you a 112.5 kW capacity, which also gives you a little additional headroom.

If you foresee substantial near-term growth, consider a modular UPS. These come in two flavors: a frame sized for more than you need, but with physical UPS and battery modules installed only as required, or a system of higher total capacity, but with firmware-configured to limit it to a lesser load until you need more. Either way, you only pay for what you need now and buy the additional capacity as it's required.

The savings are not just capital cost. A UPS unit also runs more efficiently when it's loaded to higher capacity, so you save in electrical operating costs as well. Of course, with a 2N redundant UPS, you'll actually run each UPS at half the total load, which makes it even more important to size correctly. It can be very inefficient to run below 40%.

The last consideration for proper UPS unit sizing is generator loading. Different UPS designs present different electrical characteristics to a generator. Your electrical engineer or facilities electrician will need to examine both the UPS and generator characteristics to make sure the generator won't stall when the UPS load is suddenly switched to it in an emergency.